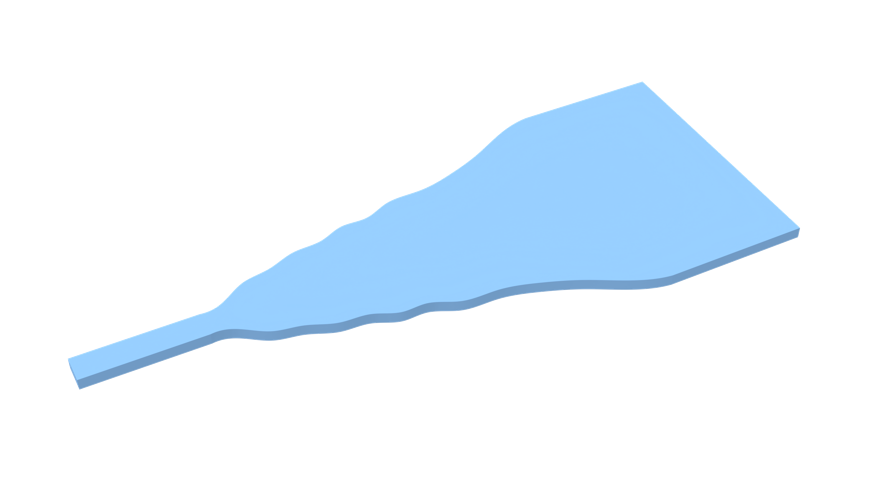

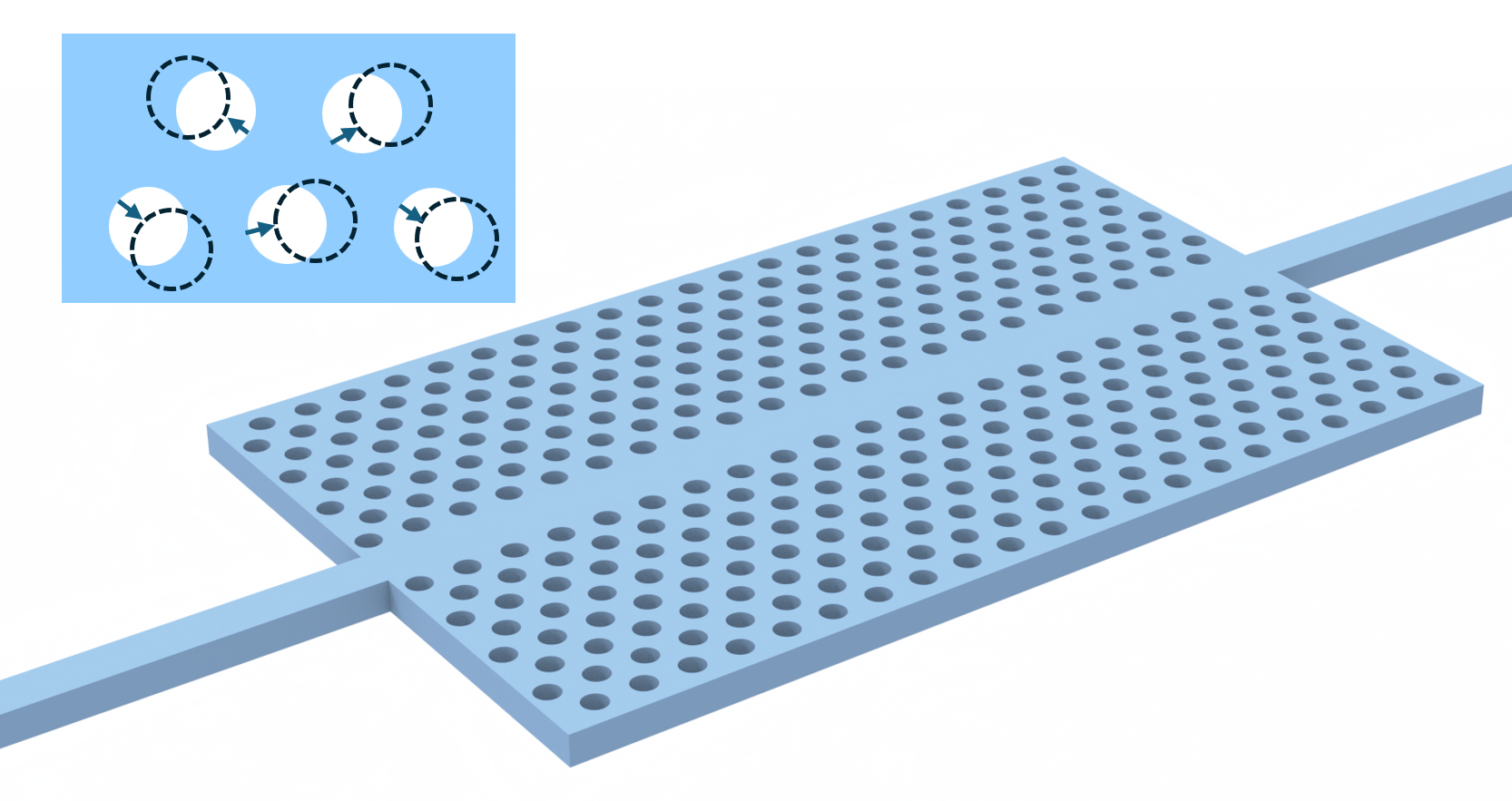

In this notebook, we will use inverse design to optimize coupling from a silicon waveguide to a photonic crystal slab.

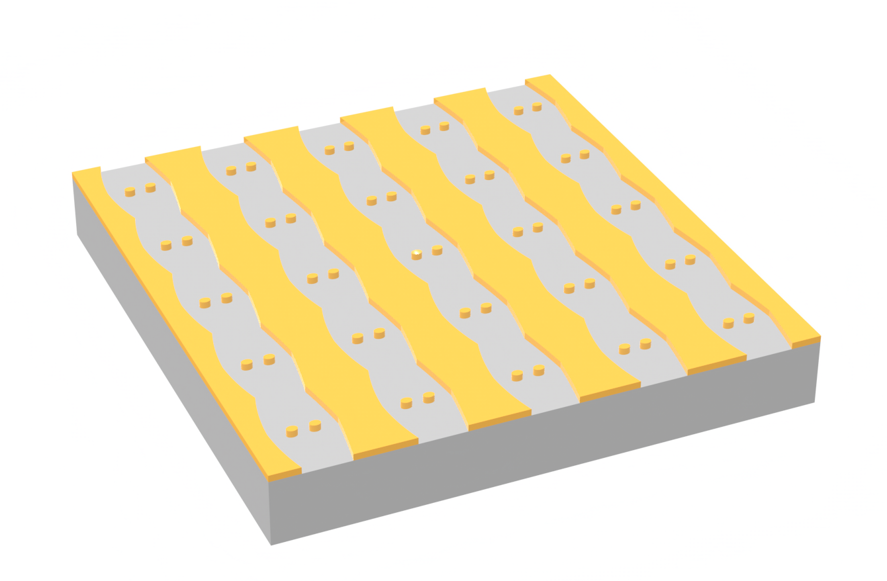

We'll first set up a very simple photonic crystal in a silicon slab.

Then, we'll maximize the transmitted flux through the crystal at a frequency just above the bandgap.

Our degrees of freedom will be the center of the holes cut in the photonic crystal, but modifying this example, one can easily adjust the radius of each hole as well as an extra design parameter.

If you are unfamiliar with inverse design, we also recommend our intro to inverse design tutorials and our primer on automatic differentiation with tidy3d.

import autograd

# we'll use autograd for automatic differentiation, so derivative-traced numpy operations will use autograd.numpy

import autograd.numpy as anp

import matplotlib.pyplot as plt

import numpy as np

import tidy3d as td

import tidy3d.web as web

Setup¶

First, we will set up some of our global parameters for the study.

The structure will consist of a rectangular lattice of air holes in a silicon slab.

nm = 1e-3

wvl0 = 1550 * nm

a = 400 * nm

num_freqs = 151

wvl_min, wvl_max = (1400 * nm, 1700 * nm)

freq_min = td.C_0 / wvl_max

freq_max = td.C_0 / wvl_min

freqs = np.linspace(freq_min, freq_max, num_freqs)

freq0 = td.C_0 / wvl0

fwidth = freq0 / 10

run_time = 300 / fwidth

sqrt3_div2 = np.sqrt(3) / 2.0

# silicon material (for slab)

n_si = 3.48

si = td.Medium(permittivity=n_si**2)

air = td.Medium()

# radius of holes

r0 = 90 * nm

# when we optimize, the radius will vary between these two values

# for now we just constrain all radius to r0, but change these values to add more degrees of freedom

r_range = rmin, rmax = (r0, r0)

rmid = r0

# how much centers can move from the center

drmax = a / 4

# number of holes in x and y

N_rows = 15

N_cols = 19

N_cols_static = 5

# total length of the PhC region

Lx_phc = N_cols * a + a / 2

Ly_phc = N_rows * sqrt3_div2 * a + a / 2

# buffer on each side of the design region

buffer = 1.0 * wvl0

# thickness of slab

t_slab = 220 * nm

# waveguide width

w_wg = 1.3 * a

# size of simulation

Lx = Lx_phc + 2 * buffer

Ly = Ly_phc + 2 * buffer

Lz = t_slab + 2 * buffer

# define grid resolution

steps_per_unit_cell = 14

dx = a / steps_per_unit_cell

dy = a * sqrt3_div2 / steps_per_unit_cell

grid_spec = td.GridSpec(

grid_x=td.UniformGrid(dl=dx),

grid_y=td.UniformGrid(dl=dy),

grid_z=td.AutoGrid(min_steps_per_wvl=steps_per_unit_cell),

)

def make_holes(params) -> td.Structure:

"""Convenience function to make the phc holes given the design parameters."""

hole_spacing_x = a

hole_spacing_y = a * sqrt3_div2

x_slab_length, y_slab_length = (

hole_spacing_x * (N_cols + 0.5),

hole_spacing_y * N_rows,

)

start_x, start_y = (

-x_slab_length / 2 + hole_spacing_x / 2,

-y_slab_length / 2 + hole_spacing_y / 2,

)

cylinders = []

for i in range(0, N_cols):

for j in range(0, N_rows):

# depending on distance from central column, hole is either static

i_dist = abs(i - N_cols // 2)

if i_dist < ((N_cols_static) / 2):

radius = rmid

dx = dy = 0

# or optimizable

else:

radius = params[0, i, j]

dx = params[1, i, j]

dy = params[2, i, j]

x0 = dx + start_x + (i + (j % 2) * 0.5) * hole_spacing_x

y0 = dy + start_y + j * hole_spacing_y

if j != N_rows // 2:

c = td.Cylinder(

axis=2,

radius=radius,

center=(x0, y0, 0),

length=td.inf,

)

cylinders.append(c)

# use GeometryGroup since all same medium, for performance

structure = td.Structure(

geometry=td.GeometryGroup(geometries=cylinders),

medium=air,

background_medium=si, # note: we need this for correct gradients when embedded in slab

)

return structure

source = td.ModeSource(

center=(-Lx / 2 + wvl0 / 10, 0, 0),

size=(0, Ly_phc / 2.0, td.inf),

source_time=td.GaussianPulse(freq0=freq0, fwidth=fwidth),

direction="+",

)

# these monitors are just for plotting the broadband flux response, not optimizing

# FluxMonitor is not supported in autograd

slab = td.Structure(

geometry=td.Box(

center=(0, 0, 0),

size=(Lx_phc, Ly_phc, t_slab),

),

medium=si,

)

waveguide = td.Structure(

geometry=td.Box(

center=(0, 0, 0),

size=(td.inf, w_wg, t_slab),

),

medium=si,

)

mnt_flux = td.FluxMonitor(

center=(-source.center[0], 0, 0),

size=(0, td.inf, td.inf),

freqs=freqs,

name="flux",

)

# this monitor is for visualizing field patterns only

mnt_field = td.FieldMonitor(

center=(0, 0, 0),

size=(td.inf, td.inf, 0),

freqs=[freq0],

name="field",

)

# These monitors are used for the optimization

# FieldMonitor.flux is used because FluxMonitor not supported in autograd

mnt_field_flux = td.FieldMonitor(

center=(+Lx_phc / 2 - a, 0, 0),

size=(0, td.inf, td.inf),

freqs=[freq0],

name="flux",

)

def make_sim(params, optimization_mode: bool = False) -> td.Simulation:

"""Function to generate a simulation with different monitors depending on whether optimizing."""

# create the holes

holes = make_holes(params)

# decide which monitors to include

if not optimization_mode:

monitors = [mnt_flux, mnt_field]

else:

monitors = [mnt_field_flux]

return td.Simulation(

center=[0, 0, 0],

size=[Lx, Ly, Lz],

grid_spec=grid_spec,

structures=[slab, waveguide, holes],

sources=[source],

monitors=monitors,

run_time=run_time,

boundary_spec=td.BoundarySpec.pml(x=True, y=True, z=True),

symmetry=(0, -1, 1),

)

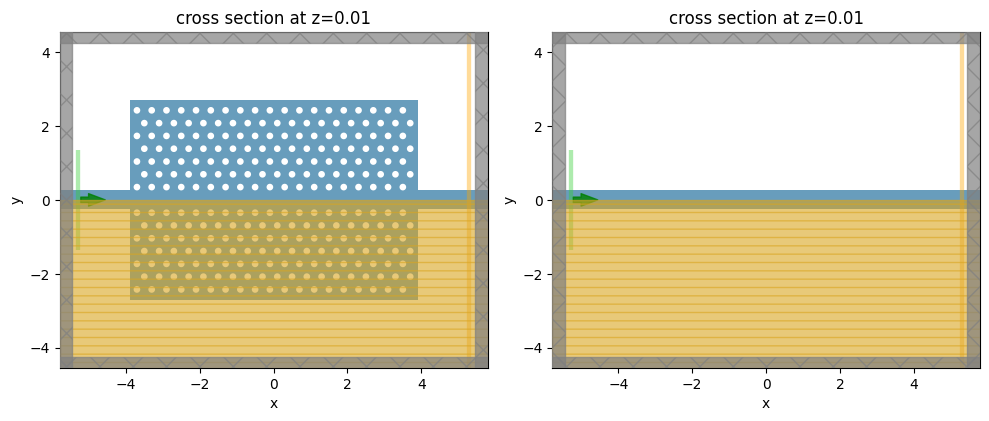

Let's make a simulation with the starting parameters, and one with just the waveguide, for normalization.

params0 = rmid * np.ones((3, N_cols, N_rows))

params0[1:] = 0.0

sim0 = make_sim(params0, optimization_mode=False)

sim_wg = sim0.updated_copy(structures=[waveguide])

_, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(10, 4))

_ = sim0.plot(z=0.01, ax=ax1)

_ = sim_wg.plot(z=0.01, ax=ax2)

plt.show()

Next, we can run these two simulations to inspect the fields and compute some normalization.

sim_data0 = web.Job(simulation=sim0, task_name="initial PhC").run()

sim_data_wg = web.Job(simulation=sim_wg, task_name="initial PhC norm").run()

10:42:11 CET Created task 'initial PhC' with task_id 'fdve-bdfaf645-4a96-46b5-aa4d-8d2277a86497' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-bdfaf645-4a9 6-46b5-aa4d-8d2277a86497'.

Output()

10:42:15 CET status = queued

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

Output()

10:42:21 CET status = preprocess

10:42:23 CET Maximum FlexCredit cost: 0.251. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

starting up solver

10:42:24 CET running solver

Output()

10:43:11 CET early shutoff detected at 68%, exiting.

status = postprocess

Output()

10:43:14 CET status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-bdfaf645-4a9 6-46b5-aa4d-8d2277a86497'.

Output()

10:43:19 CET loading simulation from simulation_data.hdf5

Created task 'initial PhC norm' with task_id 'fdve-a81df8f5-9b6e-4820-8913-aed3c39060dd' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-a81df8f5-9b6 e-4820-8913-aed3c39060dd'.

Output()

10:43:22 CET status = queued

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

Output()

10:43:28 CET status = preprocess

10:43:30 CET Maximum FlexCredit cost: 0.251. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

starting up solver

running solver

Output()

10:43:37 CET early shutoff detected at 4%, exiting.

status = postprocess

Output()

10:43:38 CET status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-a81df8f5-9b6 e-4820-8913-aed3c39060dd'.

Output()

10:43:42 CET loading simulation from simulation_data.hdf5

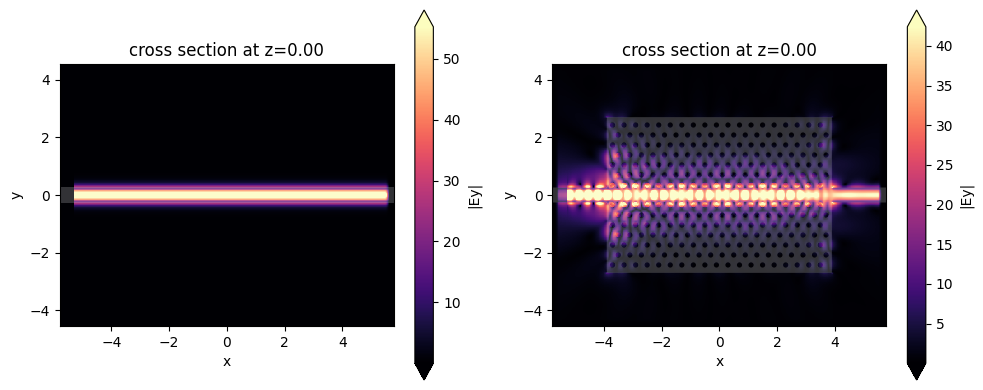

_, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(10, 4))

_ = sim_data_wg.plot_field("field", field_name="Ey", val="abs", ax=ax1)

_ = sim_data0.plot_field("field", field_name="Ey", val="abs", ax=ax2)

plt.show()

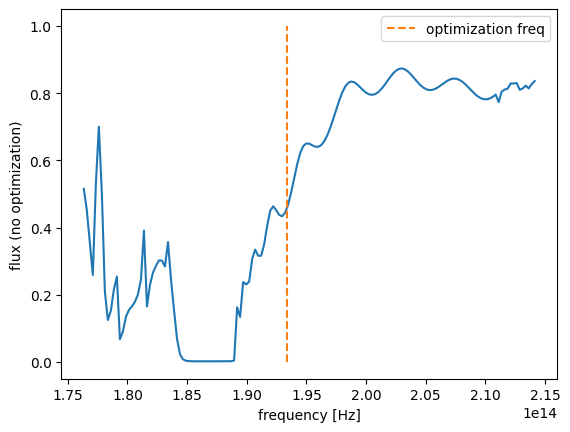

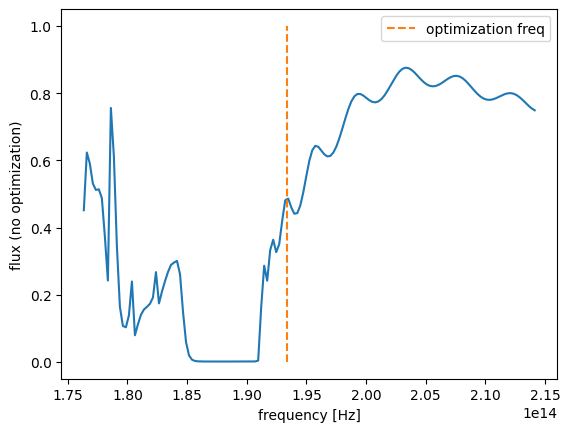

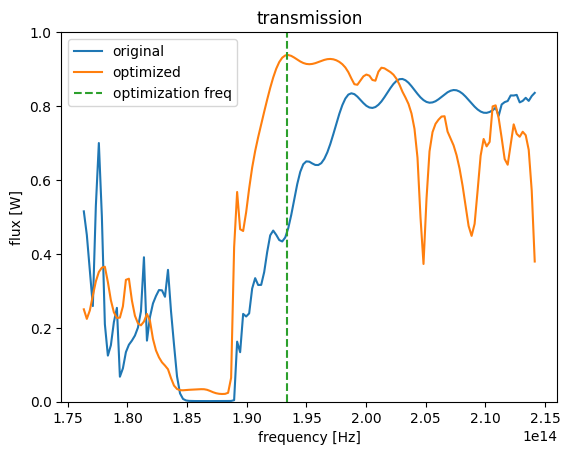

Let's visualize the transmission. We can clearly see the bandgap, but above the bandgap, the transmission is not great. We will optimize transmitted flux at the orange line.

Note: one can also do this with

ModeMonitorand include a broadband objective.

flux_wg = abs(sim_data_wg["flux"].flux)

flux0 = abs(sim_data0["flux"].flux) / flux_wg

flux0.plot(x="f")

plt.ylabel("flux (no optimization)")

plt.plot([freq0, freq0], [0, 1], linestyle="--", label="optimization freq")

plt.legend()

plt.show()

flux_wg = abs(sim_data_wg["flux"].flux)

flux0 = abs(sim_data0["flux"].flux) / flux_wg

flux0.plot(x="f")

plt.ylabel("flux (no optimization)")

plt.plot([freq0, freq0], [0, 1], linestyle="--", label="optimization freq")

plt.legend()

plt.show()

flux0_freq0 = flux_wg.interp(f=freq0).item()

print(flux0_freq0)

1.0000138821140412

The normalization flux is about 1, which is as expected as our ModeSource takes this into account.

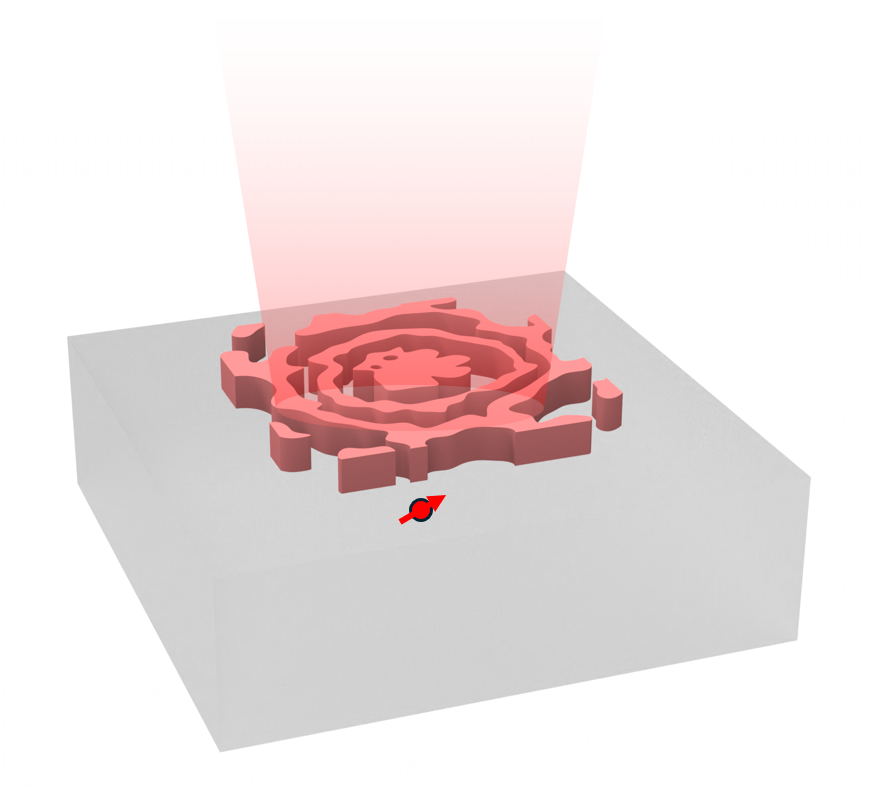

Optimization¶

Next, we will define our inverse design problem. We'll adjust the centers and radii (if desired) to maximize flux at freq0, normalized by our straight waveguide transmission.

def objective(params: anp.ndarray) -> float:

"""Maximize flux in -y, minimize flux in +x."""

sim = make_sim(params, optimization_mode=True)

sim_data = web.run(sim, task_name="phc_adjoint", verbose=False)

flux_measure_freq0 = anp.sum(anp.abs(sim_data["flux"].flux.data))

return flux_measure_freq0 / flux_wg.interp(f=freq0).item()

As always, we can use one line of autograd code to get a function that gives the value and gradient of our objective when passed some parameters.

val_grad = autograd.value_and_grad(objective)

And then we can use this function in our gradient-ascent optimizer using optax.

We first set up the optimizer parameters.

import optax

from autograd.tracer import getval

# hyperparameters

num_steps = 10

learning_rate = a / 40

# note: the step size needs to be quite low because of the direct modification of geometric parameter

# initialize adam optimizer with starting parameters

params = np.array(params0).copy()

optimizer = optax.adam(learning_rate=learning_rate)

opt_state = optimizer.init(params)

# store history

objective_history = []

param_history = [params]

data_history = []

And then run the optimization in a for loop (note: to continue optimization, you can always re-run this cell assuming params is set to the last parameters from your previous run.

%%time

for i in range(num_steps):

print(f"step = {i + 1}")

# compute gradient and current objective function value

value, gradient = val_grad(params)

gradient = np.array(gradient)

# outputs

print(f"\tJ = {value:.4e}")

print(f"\tgrad_norm = {np.linalg.norm(gradient):.4e}")

# compute and apply updates to the optimizer based on gradient

updates, opt_state = optimizer.update(-gradient, opt_state, params)

params[:] = optax.apply_updates(params, updates)

params[0] = anp.clip(params[0], rmin, rmax)

params[1:] = anp.clip(params[1:], -drmax, drmax)

# save history

objective_history.append(value)

param_history.append(params)

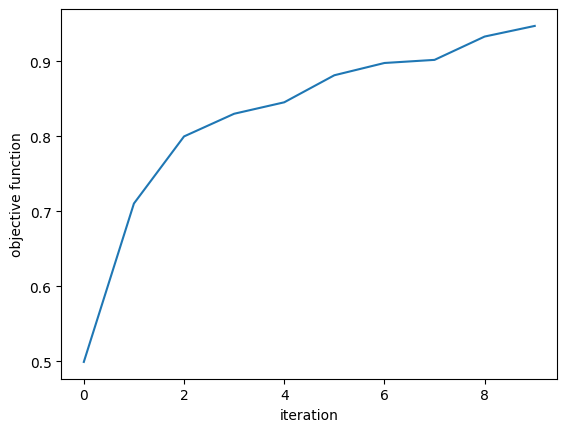

step = 1 J = 4.9913e-01 grad_norm = 1.3225e+01 step = 2 J = 7.1040e-01 grad_norm = 7.6651e+00 step = 3 J = 7.9986e-01 grad_norm = 5.9899e+00 step = 4 J = 8.3010e-01 grad_norm = 6.2971e+00 step = 5 J = 8.4537e-01 grad_norm = 7.5235e+00 step = 6 J = 8.8144e-01 grad_norm = 5.2108e+00 step = 7 J = 8.9780e-01 grad_norm = 5.2837e+00 step = 8 J = 9.0196e-01 grad_norm = 8.0595e+00 step = 9 J = 9.3306e-01 grad_norm = 2.9615e+00 step = 10 J = 9.4724e-01 grad_norm = 2.0609e+00 CPU times: user 14min 39s, sys: 8.75 s, total: 14min 48s Wall time: 24min 23s

plt.plot(objective_history)

plt.xlabel("iteration")

plt.ylabel("objective function")

plt.show()

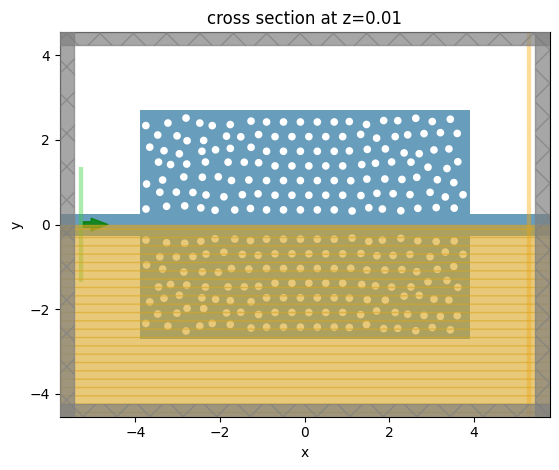

We can grab the last simulation from the parameter history and visualize the fields and flux values over the full spectrum.

params_final = param_history[-1]

sim_final = make_sim(params_final, optimization_mode=False)

_ = sim_final.plot(z=0.01)

plt.show()

sim_data_final = web.run(sim_final, task_name="phc")

11:11:03 CET Created task 'phc' with task_id 'fdve-a6cff05a-90ae-46b1-af30-16656cb2ce1f' and task_type 'FDTD'.

View task using web UI at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-a6cff05a-90a e-46b1-af30-16656cb2ce1f'.

Output()

11:11:06 CET status = queued

To cancel the simulation, use 'web.abort(task_id)' or 'web.delete(task_id)' or abort/delete the task in the web UI. Terminating the Python script will not stop the job running on the cloud.

Output()

11:11:11 CET status = preprocess

11:11:13 CET Maximum FlexCredit cost: 0.251. Use 'web.real_cost(task_id)' to get the billed FlexCredit cost after a simulation run.

starting up solver

11:11:14 CET running solver

Output()

11:11:34 CET early shutoff detected at 28%, exiting.

11:11:35 CET status = postprocess

Output()

11:11:36 CET status = success

View simulation result at 'https://tidy3d.simulation.cloud/workbench?taskId=fdve-a6cff05a-90a e-46b1-af30-16656cb2ce1f'.

Output()

11:11:41 CET loading simulation from simulation_data.hdf5

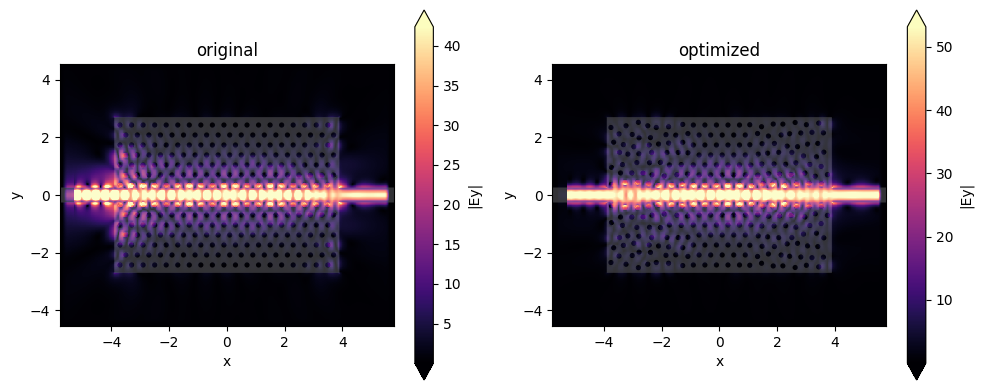

_, (ax1, ax2) = plt.subplots(1, 2, tight_layout=True, figsize=(10, 4))

# vmax = 30

ax1 = sim_data0.plot_field("field", field_name="Ey", val="abs", ax=ax1)

ax2 = sim_data_final.plot_field("field", field_name="Ey", val="abs", ax=ax2)

ax1.set_title("original")

ax2.set_title("optimized")

plt.show()

The optimized fields look much smoother, with far less reflection from the input ports.

flux_final = abs(sim_data_final["flux"].flux)

flux0.plot(x="f", label="original")

flux_final.plot(x="f", label="optimized")

plt.ylim([0, 1])

plt.title("transmission")

plt.plot([freq0, freq0], [0, 1], linestyle="--", label="optimization freq")

plt.legend()

plt.show()

And the new transmission (orange) is far higher above the bandgap, meaning that this new device is coupling light much better from the input waveguide!